The Lycoming Overhaul Manual is a comprehensive guide for maintaining and overhauling Lycoming aircraft engines, ensuring safety, performance, and compliance with aviation standards. It provides detailed procedures, specifications, and essential information for mechanics and aircraft owners to perform overhauls effectively. Regular updates by Lycoming ensure the manual remains current with technical advancements and regulatory requirements.

Purpose and Scope of the Manual

The Lycoming Overhaul Manual provides detailed procedures, specifications, and guidelines for the complete overhaul of Lycoming aircraft engines. Its purpose is to ensure compliance with aviation standards, safety, and optimal engine performance. The manual covers disassembly, inspection, repair, and reassembly processes, offering clear instructions for mechanics and aircraft owners to maintain engine reliability and extend service life effectively.

Overview of Lycoming Engines and Their Importance in Aviation

Lycoming engines are renowned for their reliability and performance in general aviation, powering thousands of aircraft worldwide. Their robust design and fuel efficiency make them a preferred choice for pilots and aircraft manufacturers. As a trusted leader in aviation, Lycoming engines play a critical role in ensuring safe and efficient flight operations, making their maintenance and overhaul essential for continued airworthiness and safety.

General Description of Lycoming Engines

Lycoming engines are renowned for their reliability, durability, and performance in various aviation applications. Known for their air-cooled design, they offer lightweight and robust power solutions for aircraft, ensuring optimal efficiency and longevity.

Key Features and Components of Lycoming Engines

Lycoming engines are distinguished by their air-cooled design, forged steel crankshafts, and precision-engineered cylinders. They feature fuel injection systems, turbochargers for high-altitude performance, and durable components designed for longevity. The engines also incorporate advanced ignition systems and lightweight materials, ensuring reliability, fuel efficiency, and optimal power delivery across various aviation applications.

Model Variations and Their Specific Overhaul Requirements

Lycoming engines vary across models like the O-320, O-360, and IO-540, each requiring distinct overhaul procedures. The IO-540 series, with fuel injection, demands precise fuel system inspection. Turbocharged models need additional turbine maintenance. Variations in cylinder configurations and crankcases necessitate model-specific tools and adherence to unique inspection criteria outlined in the manual to ensure proper restoration of engine performance and longevity.

Tools and Equipment Needed for Overhaul

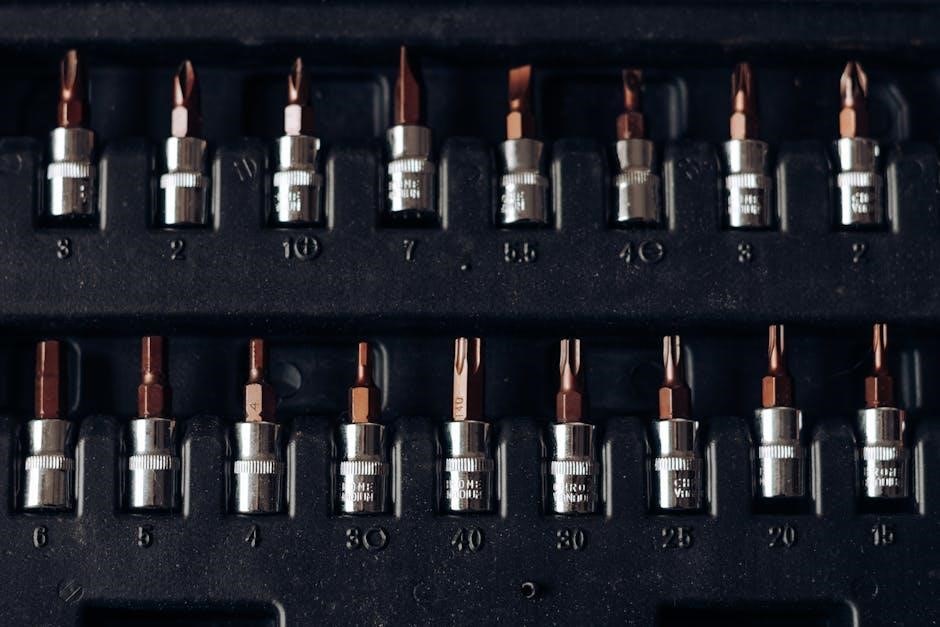

The Lycoming overhaul requires specialized tools like hydraulic testers, piston pin pullers, and engine stands. Essential equipment includes precision gauges, torque wrenches, and a clean, well-organized workshop setup.

Specialized Tools Required for Lycoming Engine Overhaul

The Lycoming overhaul demands specific tools like hydraulic testers, ring compressors, and piston pin pullers. Precision gauges, torque wrenches, and valve spring compressors are also essential. These tools ensure accurate disassembly, inspection, and reassembly. They can be sourced from Lycoming-approved distributors or aviation suppliers to maintain compliance with overhaul standards and procedures outlined in the manual.

Essential Equipment and Workshops Setup

A well-equipped workshop is critical for a successful Lycoming engine overhaul. Essential equipment includes sturdy workbenches, hoists, and precision measuring tools. A clean, well-organized workspace with proper lighting and storage for components is vital. Additionally, access to digital manuals, service bulletins, and specialized software ensures compliance with Lycoming’s standards and facilitates efficient workflow during the overhaul process.

Overhaul Procedures

The overhaul involves a systematic approach, starting with disassembly, inspection, and cleaning, followed by reassembly and testing to ensure engine reliability and optimal performance.

Step-by-Step Disassembly and Inspection Process

Disassembly begins with removing external components, such as cowling and accessories, followed by cylinder heads and pistons. Each part is meticulously inspected for wear, cracks, or corrosion. Measurements are taken to ensure compliance with tolerance specifications. Non-conforming parts are documented for replacement or repair, ensuring adherence to Lycoming’s service bulletins and technical standards.

Reassembly and Testing Procedures

Reassembly follows a precise sequence, starting with internal components like crankshafts and camshafts, ensuring proper torque values and bolt tightening sequences. Each step adheres to Lycoming’s specifications and service bulletins. Post-reassembly, engines undergo rigorous testing, including ground runs and performance checks. Leak tests and compression checks confirm functionality. Final inspections and documentation complete the process, ensuring reliability and safety.

Specifications and Technical Data

Lycoming engines require precise specifications, including torque values, bolt tightening sequences, and critical tolerances. Adherence to these ensures optimal performance, safety, and compliance with aviation standards.

Important Tolerances and Clearances

Lycoming engines require precise tolerances and clearances during overhaul to ensure optimal performance and longevity. Critical areas include crankshaft, camshaft, and cylinder dimensions. Proper measurement tools are essential to verify specifications. Deviations can lead to engine failure or reduced efficiency. Always refer to the latest manual for exact values, as tolerances vary by engine model and series.

Torque Values and Bolt Tightening Sequences

The Lycoming Overhaul Manual specifies precise torque values and tightening sequences for bolts and fasteners to ensure engine integrity. These values vary by engine model and component, requiring strict adherence to avoid damage or failure. Proper sequencing prevents uneven stress distribution, while accurate torque ensures optimal performance and longevity. Always reference the latest manual for exact specifications.

Troubleshooting Common Issues

Common issues include vapor lock in fuel-injected engines and worn components. Use compression tests and leak-down checks to identify problems. Consulting the manual ensures compliance with service letters and bulletins for critical updates and solutions.

Identifying and Resolving Typical Problems During Overhaul

Common issues during Lycoming engine overhauls include worn piston rings, cylinder damage, and faulty fuel injection components. Mechanics should use compression tests and leak-down checks to diagnose problems. Replacing superseded parts and adhering to Lycoming Service Bulletins ensures compliance. Proper tools and manual guidance are essential for resolving these issues effectively and safely.

Diagnosing Engine Performance Issues

Diagnosing performance issues involves compression tests, fuel system inspections, and examining wear on components like piston rings and cylinders. Using specialized tools and referencing Lycoming Service Letters helps identify root causes. Regular inspection intervals ensure early detection of problems, optimizing engine efficiency and safety. Adhering to manual guidelines is crucial for accurate diagnostics and effective solutions.

Safety Considerations and Precautions

Lycoming overhaul requires strict adherence to safety protocols, including handling hazardous materials and wearing PPE. Proper workshop setup and tool usage are emphasized to prevent accidents and ensure compliance with aviation standards. Regular training and updates on safety measures are essential for a safe overhaul process.

Safe Handling of Engine Components and Hazardous Materials

Proper safety practices are critical when handling Lycoming engine components and hazardous materials. Always wear personal protective equipment, including gloves and safety glasses, to prevent injuries. Ensure components are securely stored and protected from damage. Follow Lycoming’s guidelines for handling fuel, oils, and chemicals, and dispose of hazardous waste according to environmental regulations. Proper torque specifications must also be adhered to during reassembly to avoid component failure.

Personal Protective Equipment and Workshop Safety

Wearing proper personal protective equipment (PPE) is essential during Lycoming engine overhauls. This includes gloves, safety glasses, and steel-toe boots to prevent injuries. Ensure the workshop is well-ventilated and free from hazards. Keep tools and components organized to avoid tripping risks. Always follow Lycoming’s safety guidelines and use fire-resistant storage for flammable materials. A clean, organized workspace promotes efficiency and safety.

Accessing and Using Digital Manuals

Digital versions of the Lycoming Overhaul Manual are available online, offering convenient access to updated procedures and technical data. Use official Lycoming websites or trusted sources to download the latest versions, ensuring compliance with current standards and revisions; Digital manuals enhance searchability and portability for mechanics and maintenance personnel.

Downloading and Navigating the Lycoming Overhaul Manual

The Lycoming Overhaul Manual can be downloaded from the official Lycoming website or trusted aviation manual repositories. Users can navigate the manual using a detailed table of contents, ensuring quick access to specific sections. Key features include searchable text, hyperlinks for easy navigation, and clear indexing of technical specifications, procedures, and safety guidelines. Regular updates are available to ensure compliance with the latest aviation standards.

Using Online Resources and Updates

Lycoming offers digital resources, including service letters, bulletins, and part catalogs, to enhance the overhaul process. Online updates ensure mechanics have the latest technical data and revisions. Subscribers can access these resources through the Lycoming website or mobile apps, providing real-time information for accurate and efficient overhauls. Regular updates help maintain compliance with industry standards and improve engine performance.

Model-Specific Overhaul Considerations

Understanding specific overhaul requirements for each Lycoming model is crucial. Fuel-injected and turbocharged engines have distinct procedures, ensuring optimal performance and compliance with Lycoming guidelines.

Differences in Overhaul Procedures for Various Lycoming Models

Likewise, different Lycoming models require distinct overhaul approaches. Fuel-injected engines necessitate careful inspection of fuel system components, while turbocharged models demand precise turbocharger maintenance. Each model’s unique features, such as cylinder configurations or accessory drives, dictate specific tools and techniques, ensuring adherence to Lycoming’s detailed guidelines for optimal engine performance and longevity.

Special Instructions for Fuel-Injected and Turbocharged Engines

Fuel-injected engines require precise inspection of fuel system components, including injectors and lines, to ensure proper flow and pressure. Turbocharged engines demand additional scrutiny of turbocharger units, focusing on compressor and turbine blade condition. Both configurations necessitate adherence to specific torque values and cleaning procedures to prevent contamination and ensure optimal performance, as outlined in the Lycoming Overhaul Manual.

Maintenance and Inspection Schedules

Maintenance and inspection schedules ensure Lycoming engines operate safely and efficiently. Regular inspections, post-overhaul checks, and adherence to manufacturer guidelines prevent issues and optimize performance.

Post-Overhaul Maintenance Requirements

Post-overhaul maintenance requires meticulous adherence to Lycoming’s guidelines. Regular inspections every 50 hours and annual checks are crucial. Tasks include cylinder compression tests, ignition system checks, and oil analysis. Using genuine Lycoming parts and following torque specifications ensure reliability. Compliance with service bulletins and maintaining detailed records are essential for long-term engine performance and airworthiness.

Regular Inspection Intervals to Ensure Optimal Engine Performance

Regular inspections every 50 hours and annually are crucial for Lycoming engines. Check cylinder compressions, ignition systems, and oil for wear. Adhere to Lycoming’s guidelines and use genuine parts to maintain performance and safety. Proper documentation and compliance with service bulletins ensure engine longevity and airworthiness.

Supplementary Documents and Resources

Lycoming provides service letters, maintenance manuals, and parts catalogs to support engine overhaul processes. These resources ensure compliance with technical standards and offer detailed guidance for mechanics.

Service Bulletins and Mandatory Modifications

Service bulletins outline critical updates and mandatory modifications for Lycoming engines. These documents address safety improvements,

enhance performance, and ensure compliance with regulatory standards. Mechanics must review

and implement these bulletins during overhauls to maintain airworthiness

and prevent potential operational issues. Adherence is essential for

ensuring engine reliability and passenger safety.

Parts Catalogs and Replacement Guidelines

Lycoming parts catalogs provide detailed lists of components required for engine overhauls, ensuring mechanics can identify and source necessary parts. Replacement guidelines specify acceptable tolerances, interchangeability, and mandatory substitutions. Adhering to these catalogs prevents non-compliance with airworthiness standards. Regular updates reflect design improvements and supersessions, ensuring overhauls meet current specifications and safety requirements.

Frequently Asked Questions and Troubleshooting Tips

The manual addresses common queries about Lycoming engine overhaul, offering solutions to frequent issues like vapor lock and cylinder wear. Troubleshooting tips guide mechanics through diagnostic steps and repairs, ensuring efficient problem resolution and adherence to safety standards.

Common Queries About Lycoming Engine Overhaul

Common questions include Understanding overhaul procedures, identifying superseded parts, and interpreting Service Bulletins (SBs). Mechanics often seek clarification on acceptable wear limits and torque specifications. Queries about fuel injection systems, engine performance issues, and the importance of adhering to Lycoming’s Service Instructions (SI) are also prevalent. Revisions in manuals, like the Direct Drive Overhaul Manual (60294-7), frequently arise, prompting inquiries about necessary updates and compliance.

Expert Tips for a Successful Overhaul

Adhere strictly to Lycoming’s overhaul manual and Service Instructions (SI) for precise guidance. Always verify parts against the latest Parts Catalog and Service Bulletins (SBs). Use specialized tools to ensure accuracy and safety. Document every step meticulously for future reference and compliance. Regularly update your manual to incorporate the latest revisions and improvements. Attention to detail and thorough inspection are key to a reliable overhaul.

Following the Lycoming Overhaul Manual ensures a successful engine overhaul, maintaining safety, performance, and compliance. Proper adherence guarantees reliability and longevity, critical for flight safety and efficiency.

Final Checklist for a Successful Overhaul

- Verify all components meet Lycoming specifications and tolerances.

- Ensure proper torque values and bolt tightening sequences are followed.

- Inspect and replace worn or damaged parts as per manual guidelines.

- Conduct thorough performance and leak tests post-reassembly.

- Document all procedures and comply with service bulletins and updates.

Importance of Adhering to Manual Guidelines

Adhering to the Lycoming Overhaul Manual ensures safety, compliance, and optimal engine performance. Proper procedures prevent accidents, maintain regulatory compliance, and extend engine lifespan. Deviations risk engine failure, legal penalties, and compromised safety. Always follow torque specs, tolerances, and part replacements as specified to guarantee reliability and meet aviation standards.